Overview:

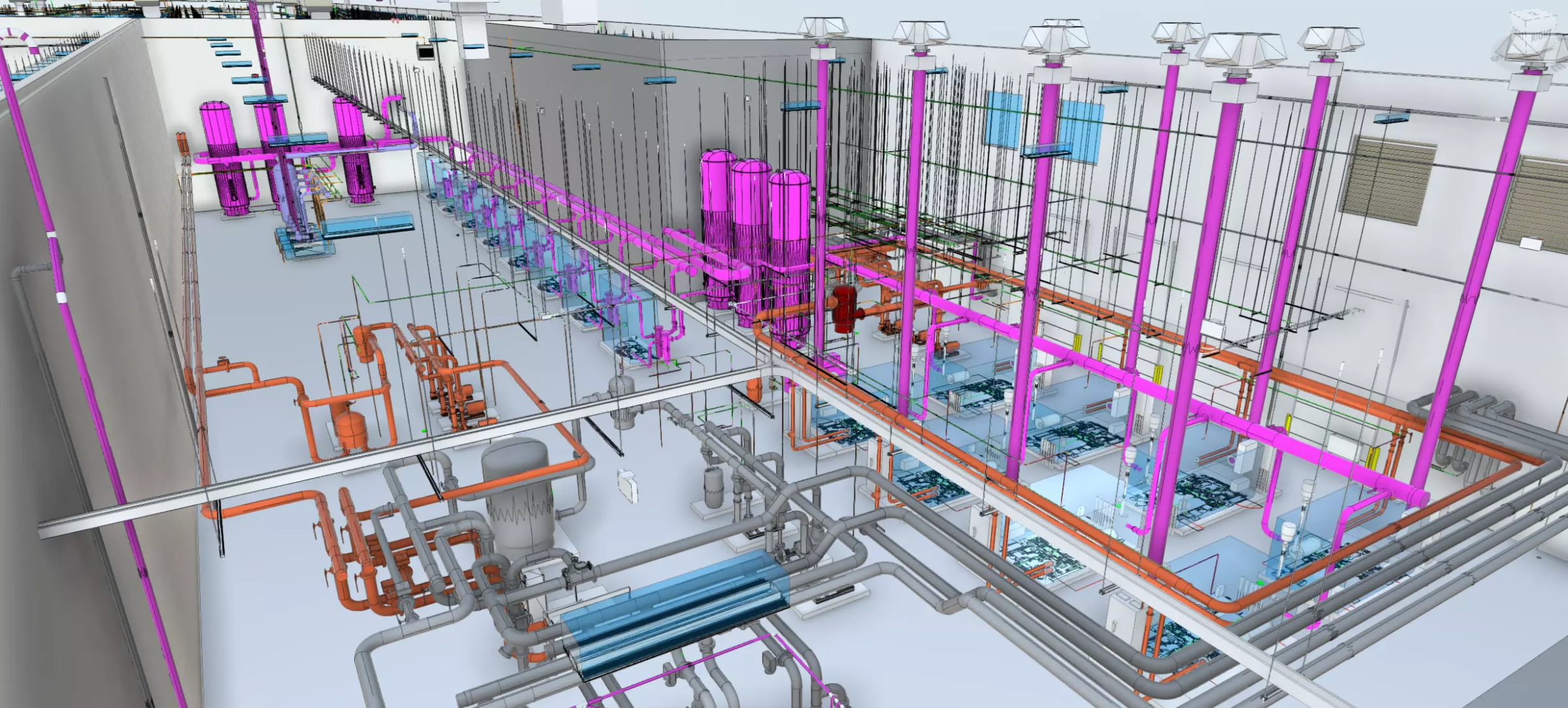

This ~$200M brownfield renovation project transformed an existing 1.3 million square foot spec warehouse into a state of the art solar panel assembly plant and storage facility. When complete, the facility supports renewable energy initiatives is forecasted to deliver 3 GW of solar modules annually. iENG designed and installed mechanical heating, cooling and ventilation, as well as the plumbing systems for offices, production spaces, assembly support and storage areas (including a hazardous chemical storage building). Our team also designed the plant utility systems which consisted of process cooling water, compressed air and vacuum.

Our design supports seven photovoltaic assembly lines, intaking wafers and outputting ready-to-use modules. This facility required coordination of more than 1,400 plant utility connections with nearly 17,000 CFM of compressed air production and 2,500 CFM of plant vacuum. The brownfield spec warehouse structure required tight virtual coordination with structural design engineers and other disciplines for equipment, duct, and piping systems across the plant.

The facility has over 50,000 square foot of office, laboratory and quality areas, including a detached chemical storage building. HVAC, plumbing and plant utility systems were designed for production spaces with high internal heat loads, process exhaust, pressurization, filtration and high humidity requirements.

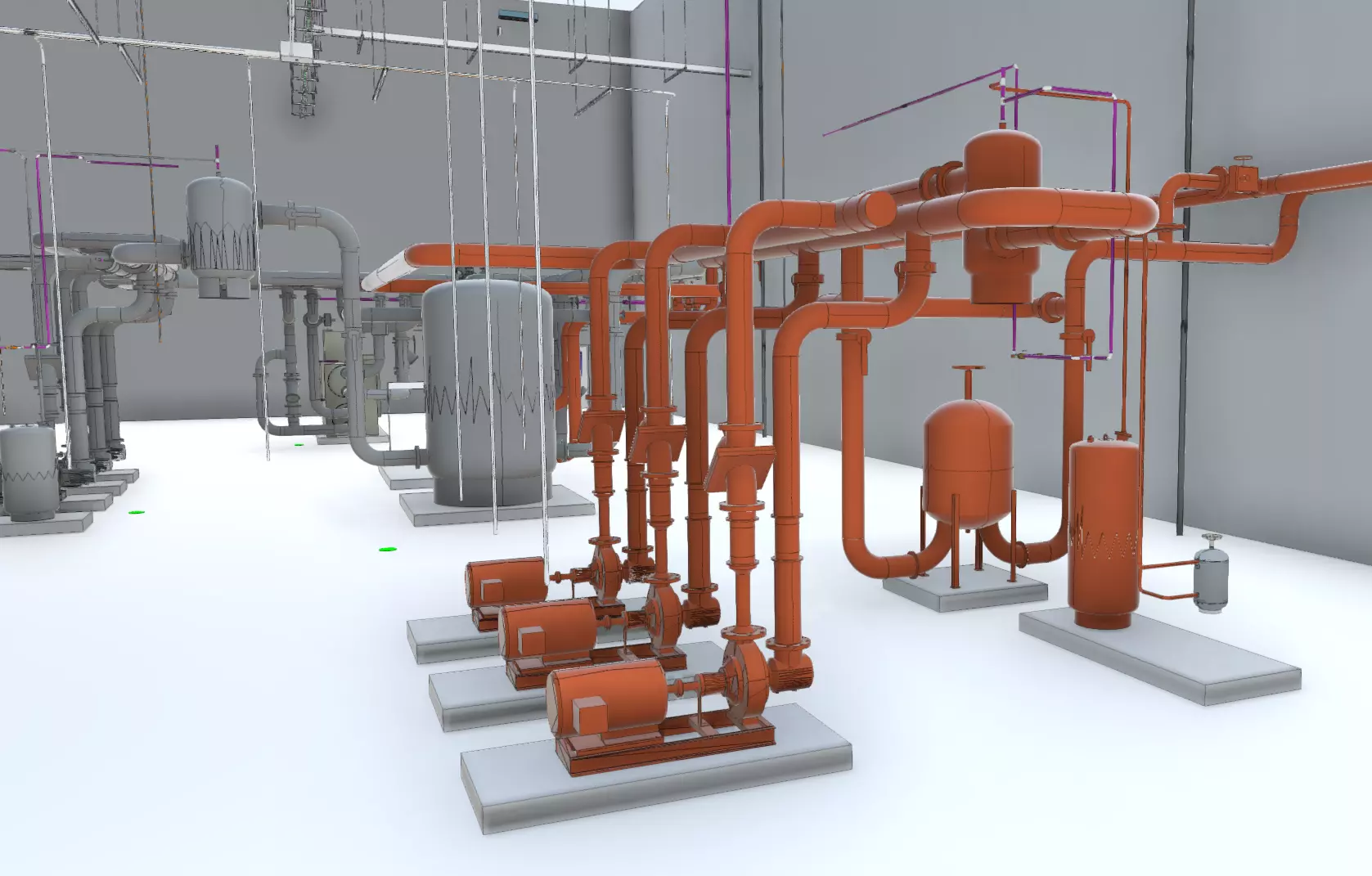

Designs for Miles - This design's large compressed air system included eight air compressors, and almost two miles of compressed-air piping. Our design also included nearly a mile of process water piping as well.