Overview:

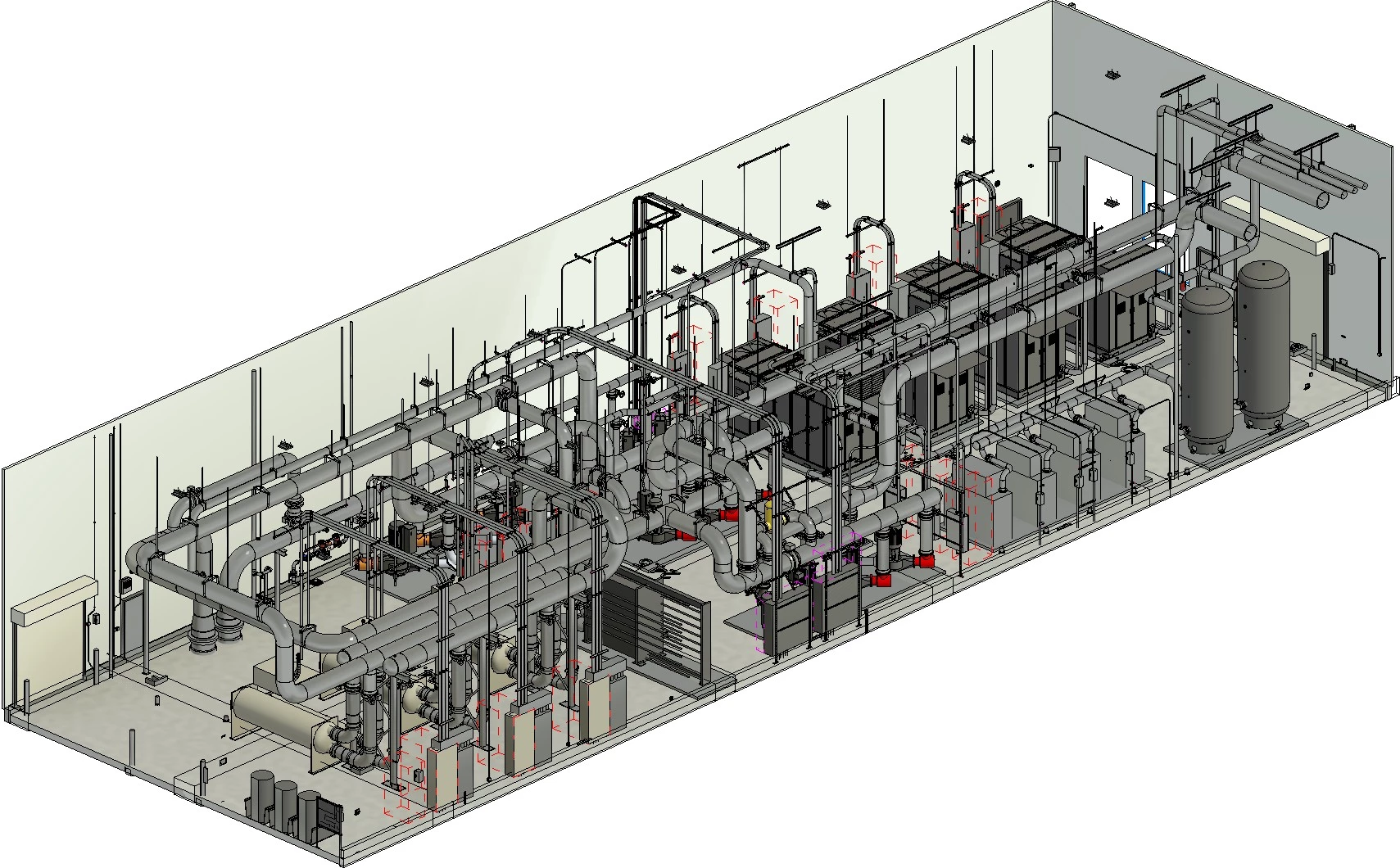

This 40 acre, $240M aluminum processing facility houses a process where large aluminum coils are stored, extruded and tested for large-scale production of cathode foil to be used in the anode side of EV batteries. The iENG airside scope included providing heating/ventilation to the warehouse, production, high0bay storage and electrical/mechanical areas, with conditioning for office space. Our process piping scope included generation/distribution of compressed air and chilled water for process equipment.

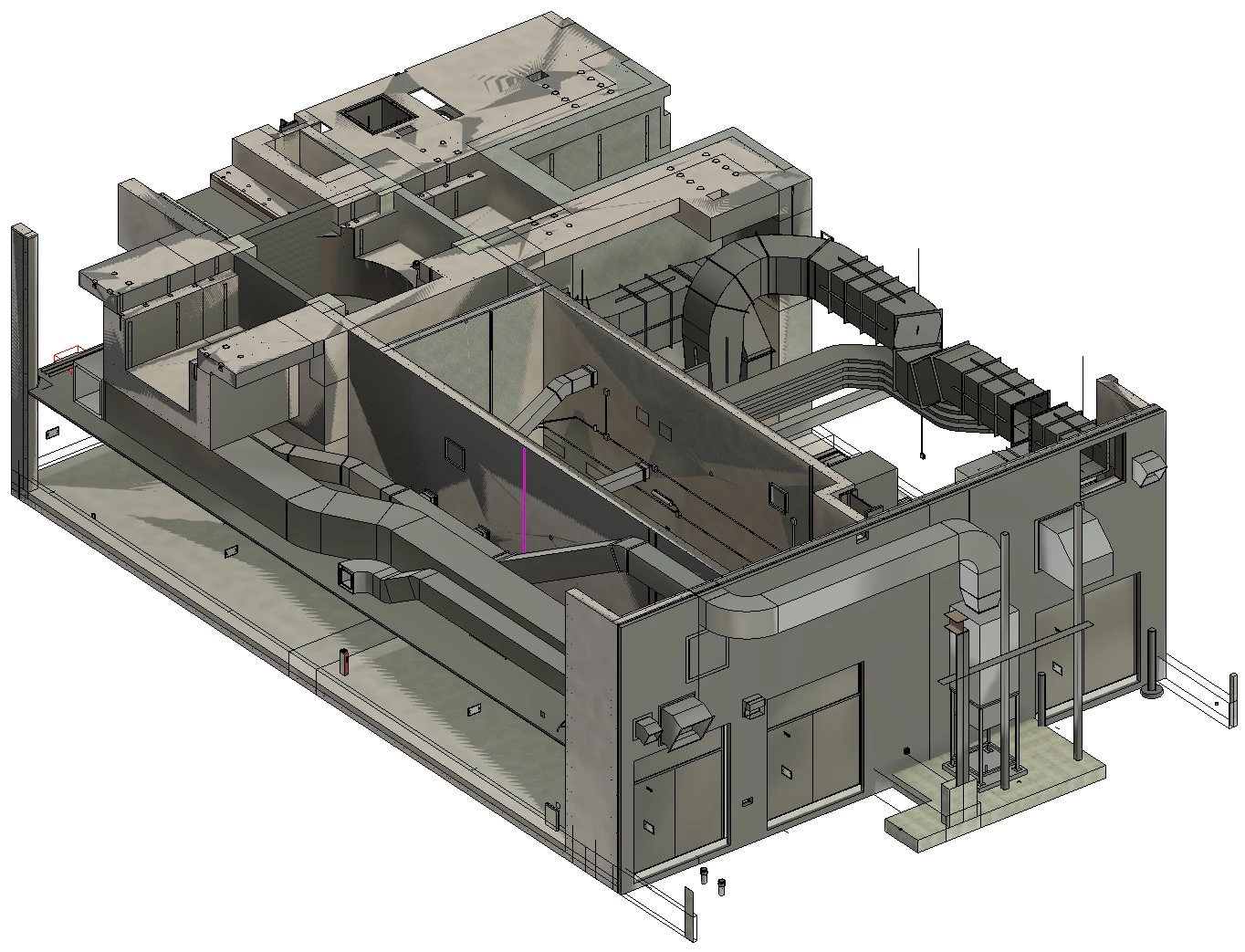

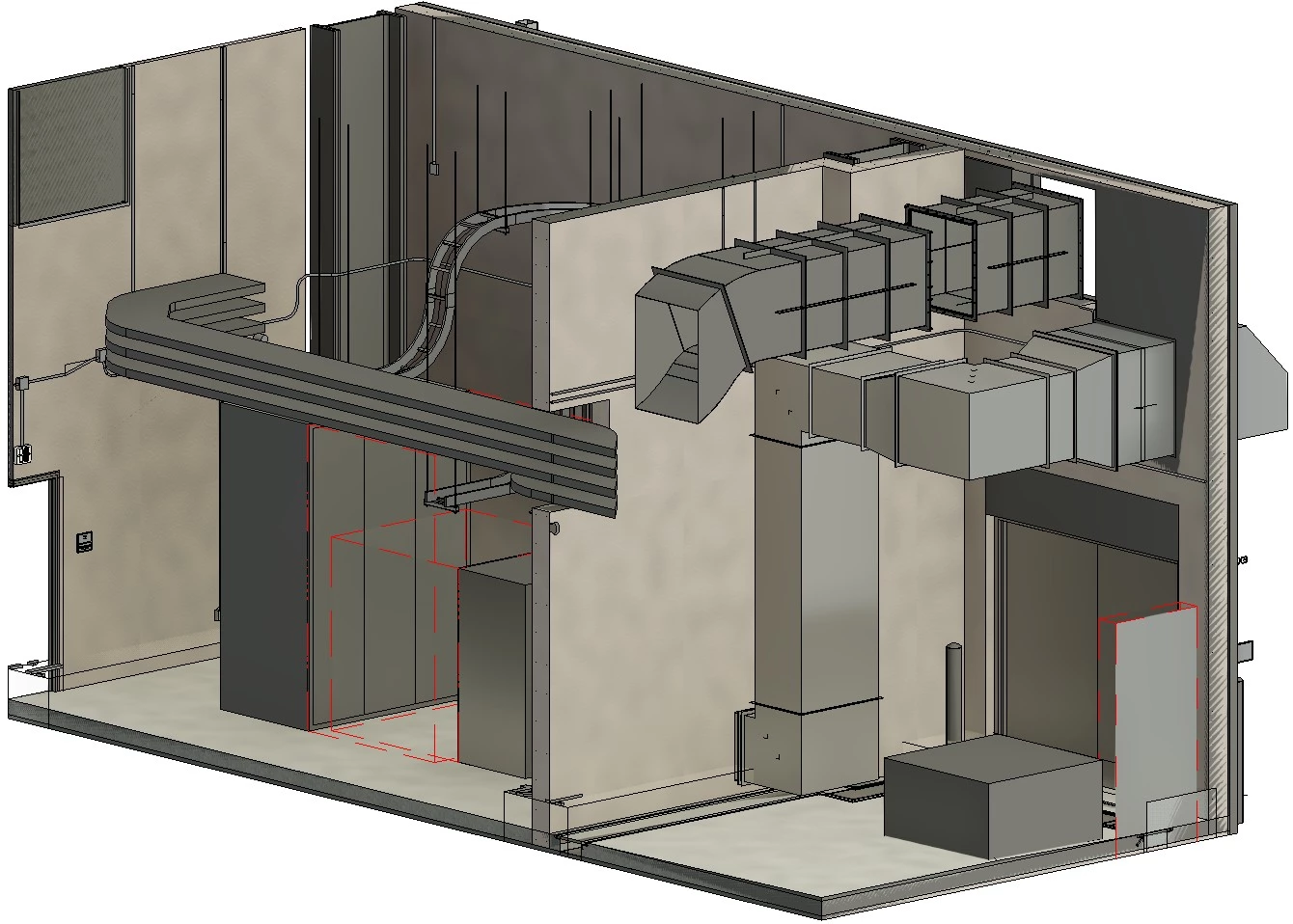

Special challenges in this project included routing ductwork through extremely tight spaces in the ‘cellar’ areas below the rolling mill floors. Our team carefully coordinated and designed makeup air ductwork, exhaust fans, and CO2 relief ductwork being hung from a concrete deck. Interestingly, the CO2 relief ductwork stands out because it provided pressure relief for the clean-agent fire suppression systems in the cellars. An additional challenge was an extensive network of fire-rated walls, which required both fire dampers (150 to be exact) and fire/smoke dampers with specialty designed custom assemblies requiring approval by an inspector prior to installation.