Our Impact:

The Vanderbilt University Medical Center project required iENG to deliver highly coordinated mechanical solutions within a complex healthcare environment. iENG was responsible for the plumbing, piping, and sheet metal scope for the fit-out of patient care areas on the 12th and 14th floors. These areas required full mechanical system integration within an architecturally constrained setting.

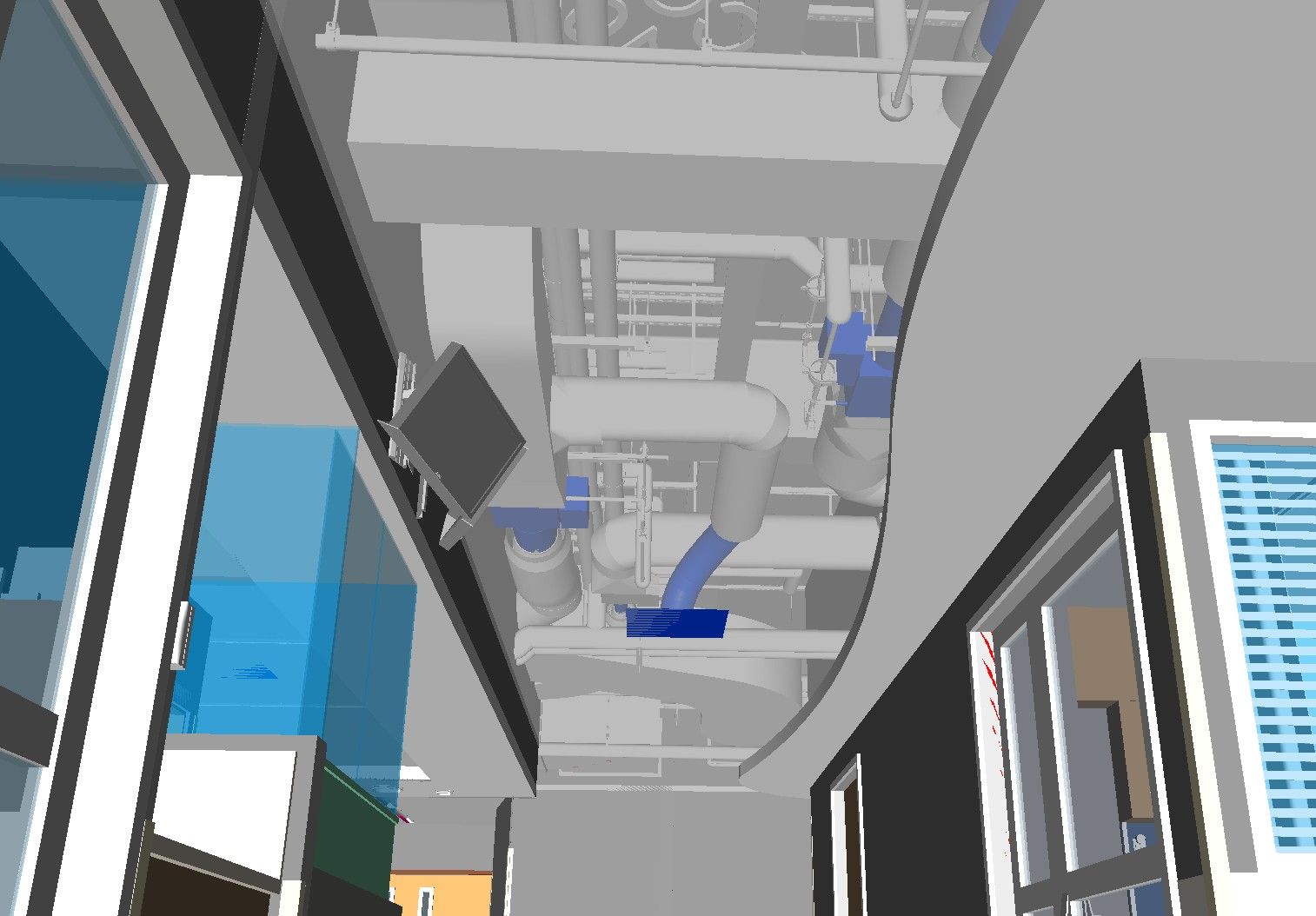

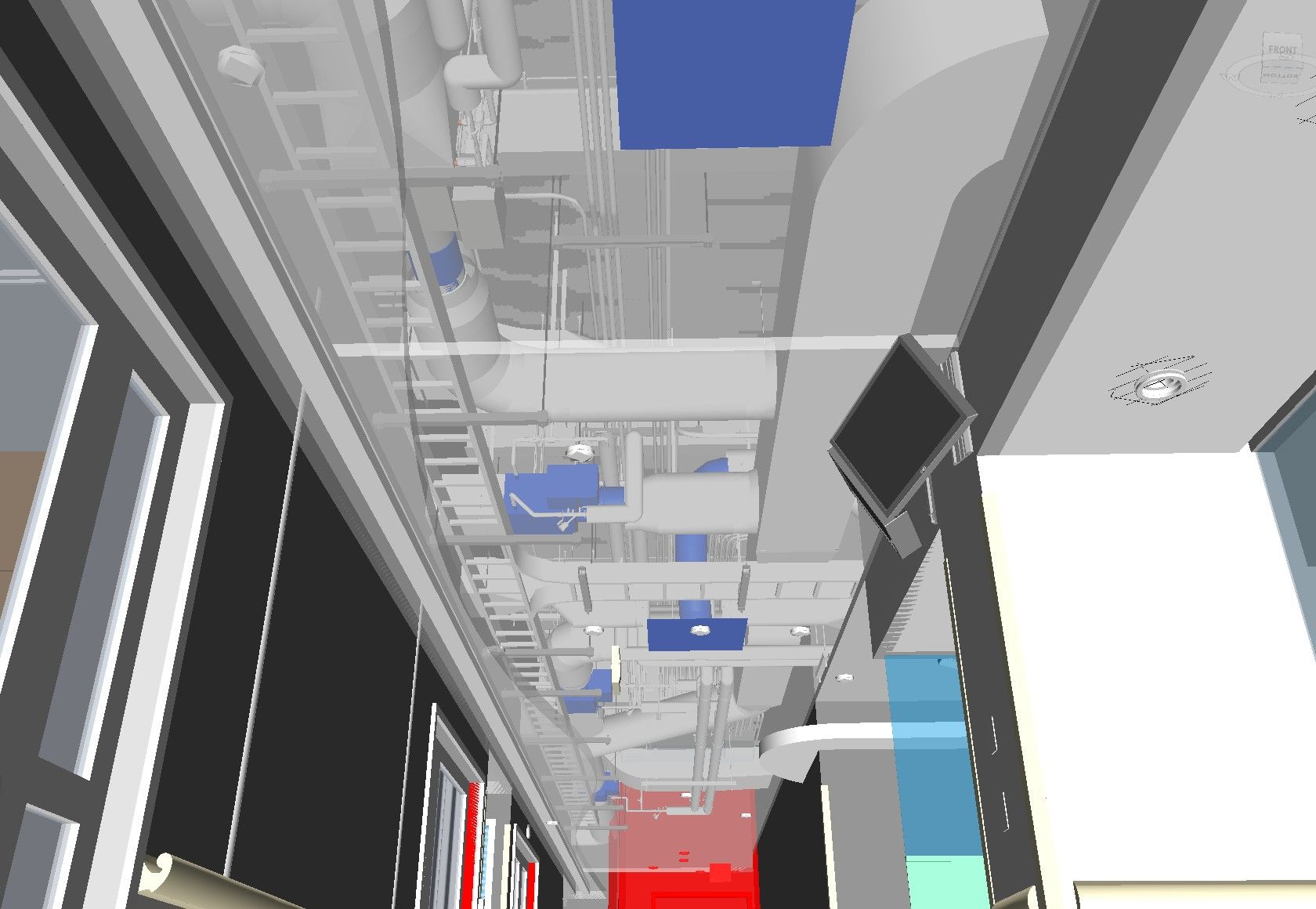

Early in the project, a collaborative team effort focused on assessing system requirements and analyzing the variables associated with the scope. Unique architectural features introduced mechanical challenges, particularly for routing ductwork and piping through non-linear geometries. Standard installation methods were often not feasible, driving the need for extensive custom fabrication to navigate angled layouts, wall penetrations, and tight pathways.

Limited floor-to-floor heights and congested above-ceiling spaces added further complexity, requiring meticulous coordination to avoid conflicts and maintain accessibility. The project also required adaptability to new client standards and close collaboration with the general contractor, supported by consistent communication to address evolving conditions.

Aggressive schedules, unexpected shifts, and real-time resolution of model discrepancies demanded continuous prioritization and problem-solving to keep work progressing. This project marked a pivotal opportunity for iENG, establishing a relationship with a local Nashville hospital and laying the foundation for future healthcare collaborations through disciplined coordination and execution in a challenging environment.

Performing in various capacities with different project scopes has benefited the iENG team enormously as the experience has provided them with a seasoned eye to readily detect challenges and identify solutions to maintain progress. This attribute positions the team as the go-to source to partner with for unique, complex, and overall, for projects of varying levels.