Our Impact:

A partnership with a confidential data center client allowed iENG to demonstrate its strategic approach to designing diverse mechanical engineering systems across two facilities in Columbus, Ohio. Each building utilized a different mechanical system, one designed with a Direct Expansion (DX) system and the other with air-cooled chillers, requiring tailored solutions within a single program.

A defining element of the project was the implementation of repeatable prefabrication strategies to streamline both detailing and installation. iENG developed a structured workflow that outlined criteria, budget considerations, VDC roles and responsibilities, and overall coordination to support consistent execution across both facilities.

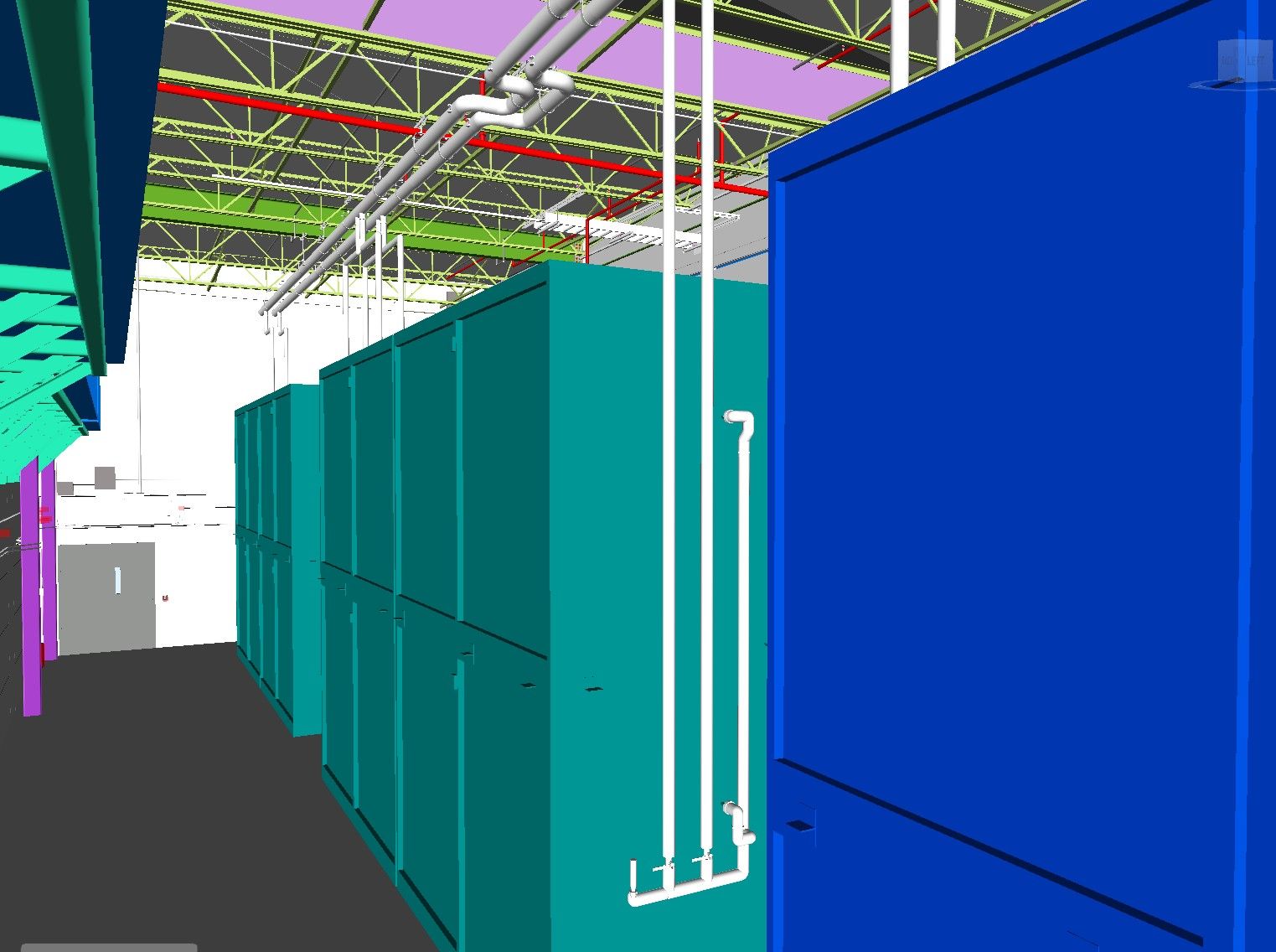

For the DX system building, the facility was designed with 225 total racks, with only 40% being unique. This limited variation allowed iENG to standardize design elements, accelerate detailing, and support repeatable installation methods. To address extensive refrigerant line runs, the team developed vertical rack assemblies that efficiently routed piping from the roof to the units, another prefabricated, repeatable solution.

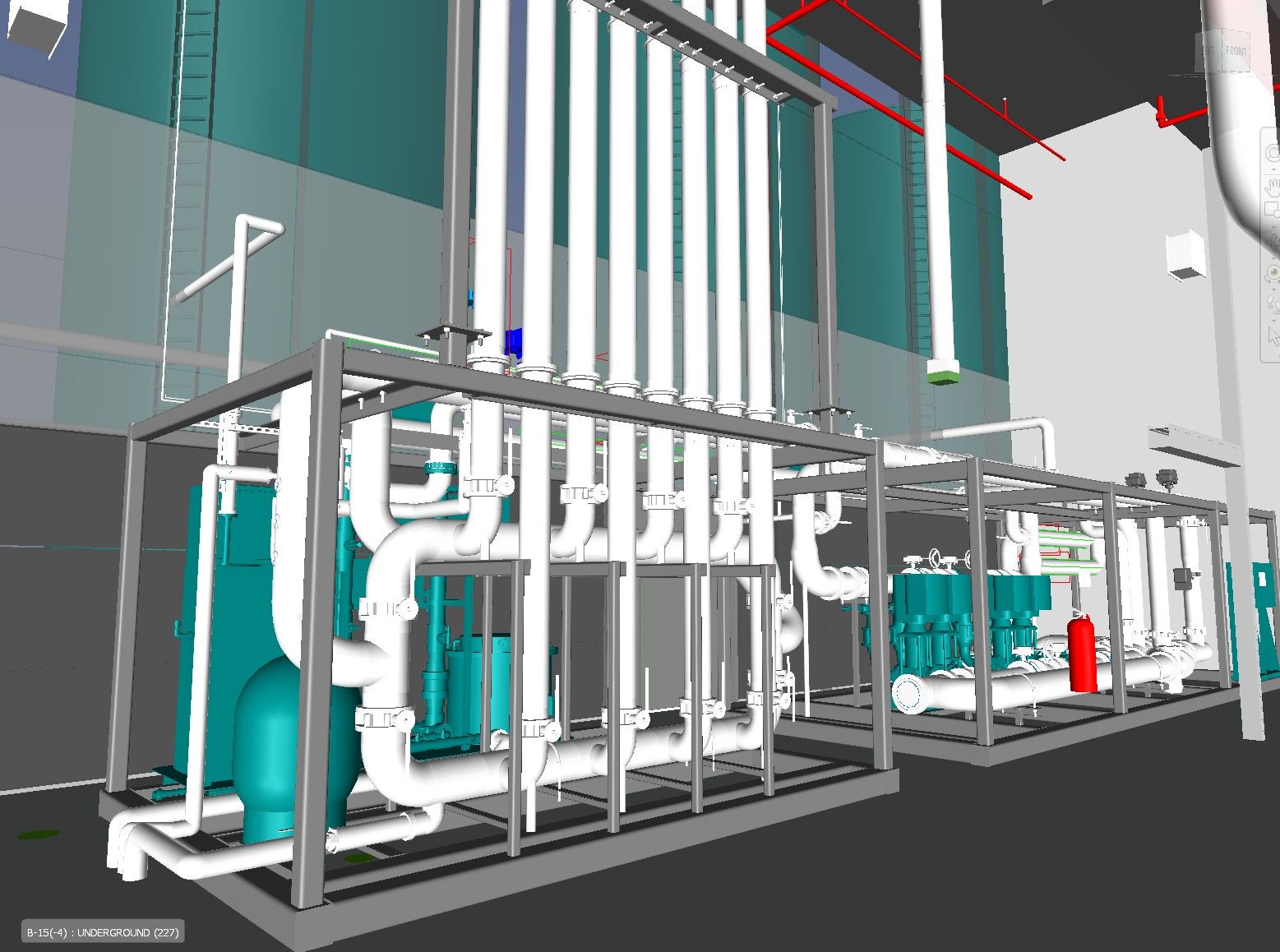

In the chilled water building, 28 air-cooled chillers were located on the roof. To support this system, iENG designed four unique pump skid assemblies that could be relocated and reused throughout the building, reducing coordination time and increasing efficiency in both detailing and prefabrication.

By leveraging technological expertise and innovative, repeatable design strategies, iENG delivered a cost-effective and highly coordinated solution while driving efficiencies in detailing, fabrication, and installation across both facilities. iENG displays why its design team is entrusted with projects that require more than technological acumen but a level of creativity and cross-functional collaboration that work together yielding unique, functional solutions.