Our Impact:

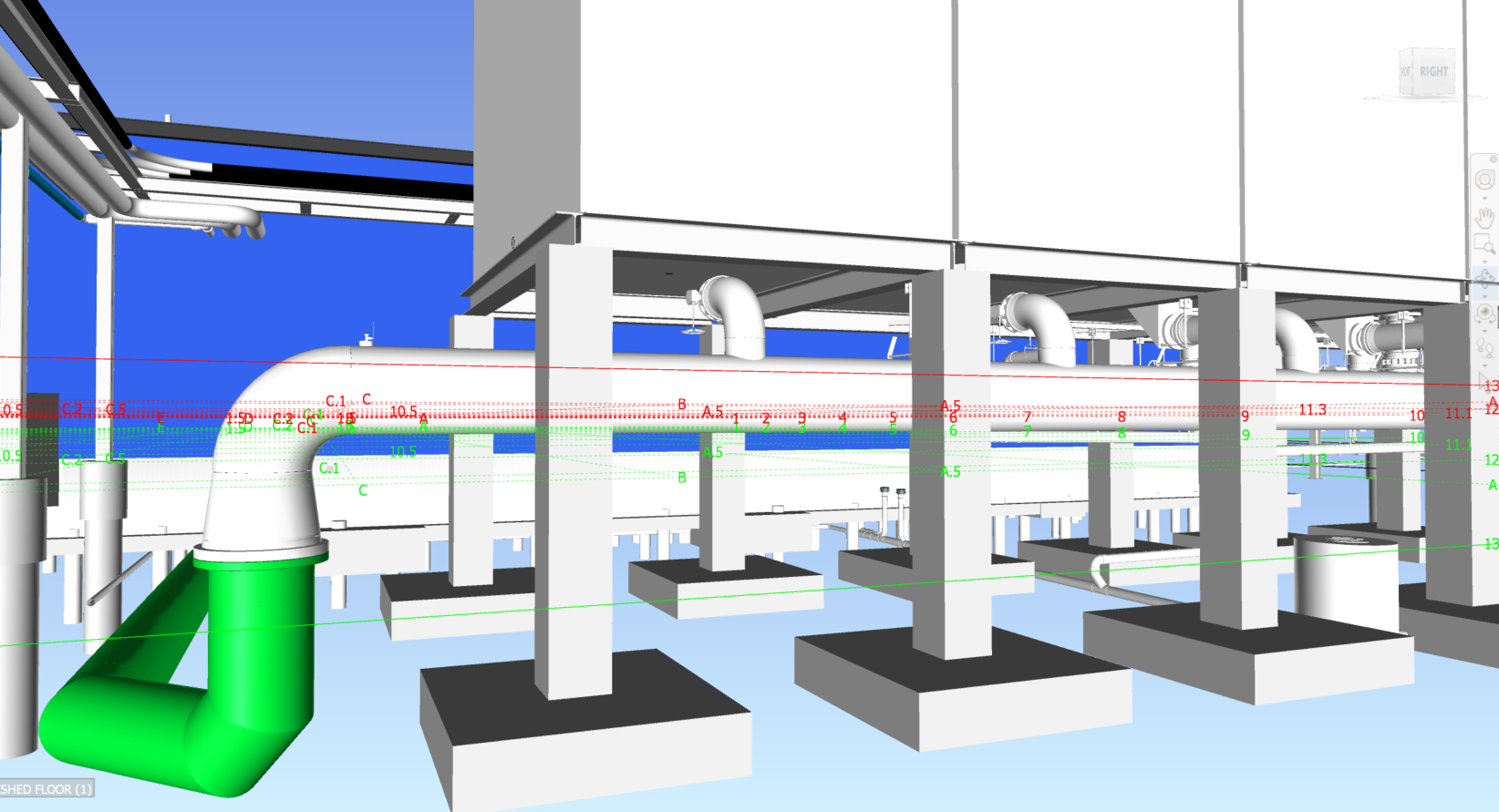

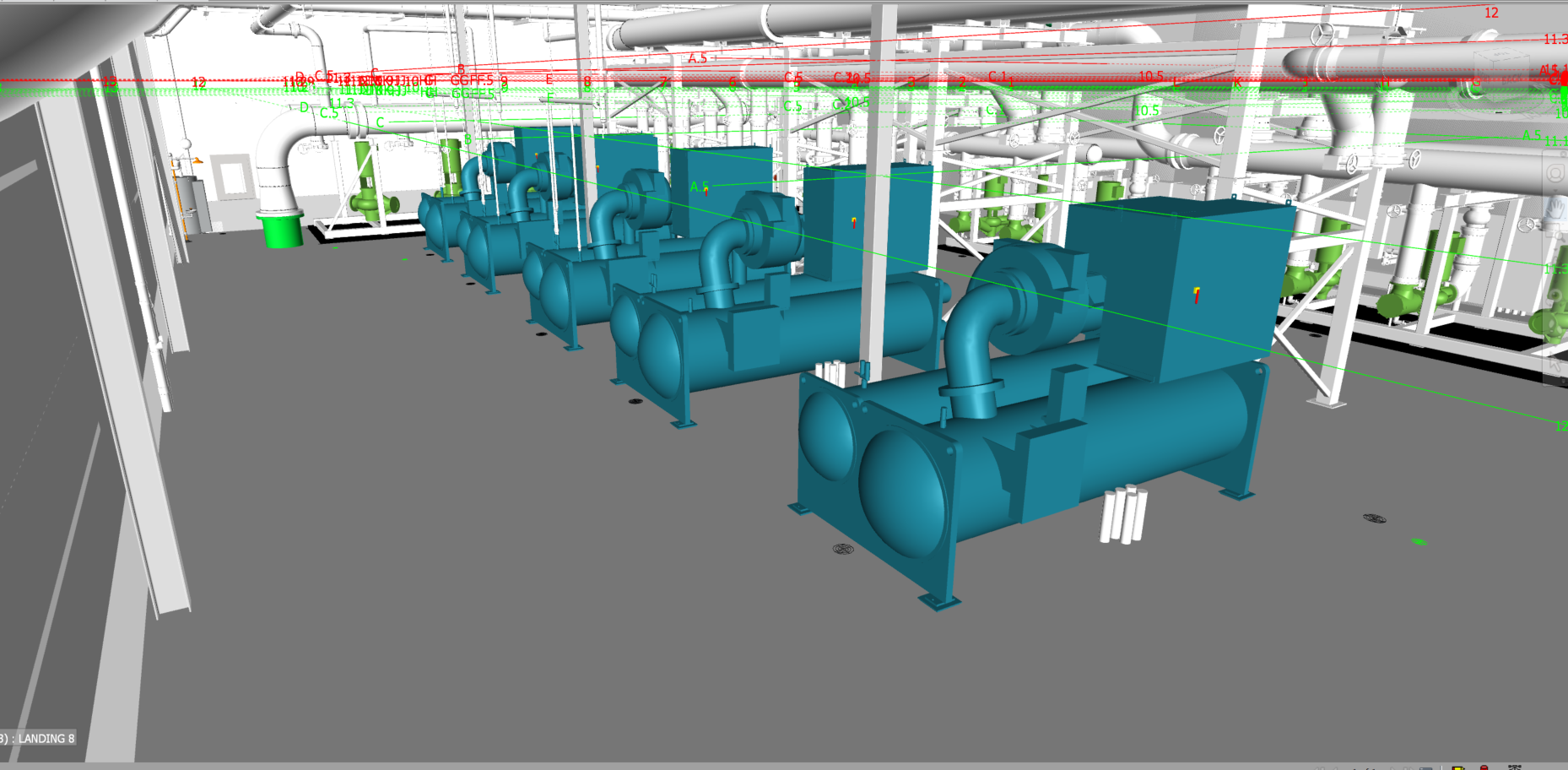

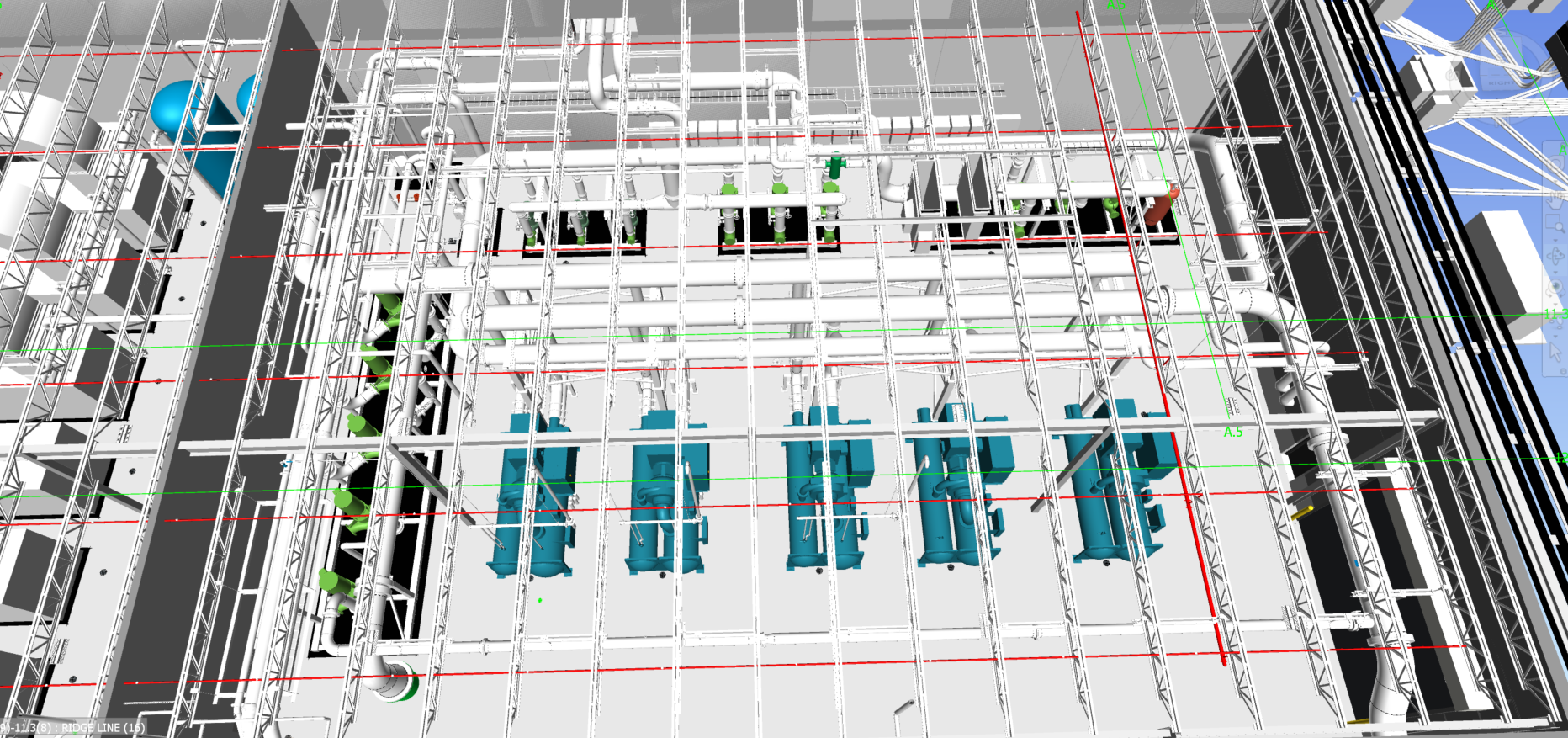

Delivering a large-scale manufacturing facility for Fiberon required strategic planning, adaptability, and disciplined coordination. iENG served as the design-build engineer for the HVAC and plumbing systems on the project, supporting a 500,000-square-foot facility designed to produce polyethylene (PE) decking and composite cladding.

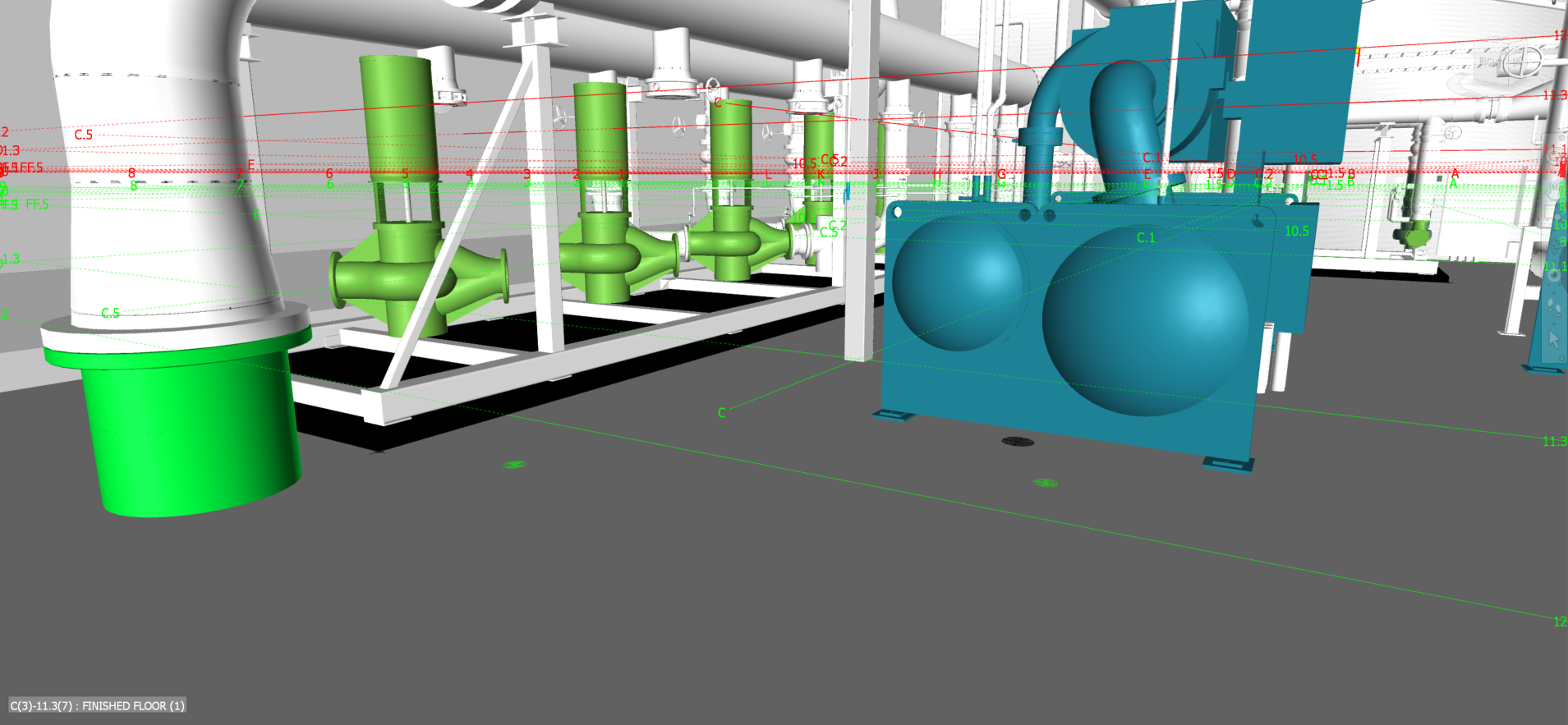

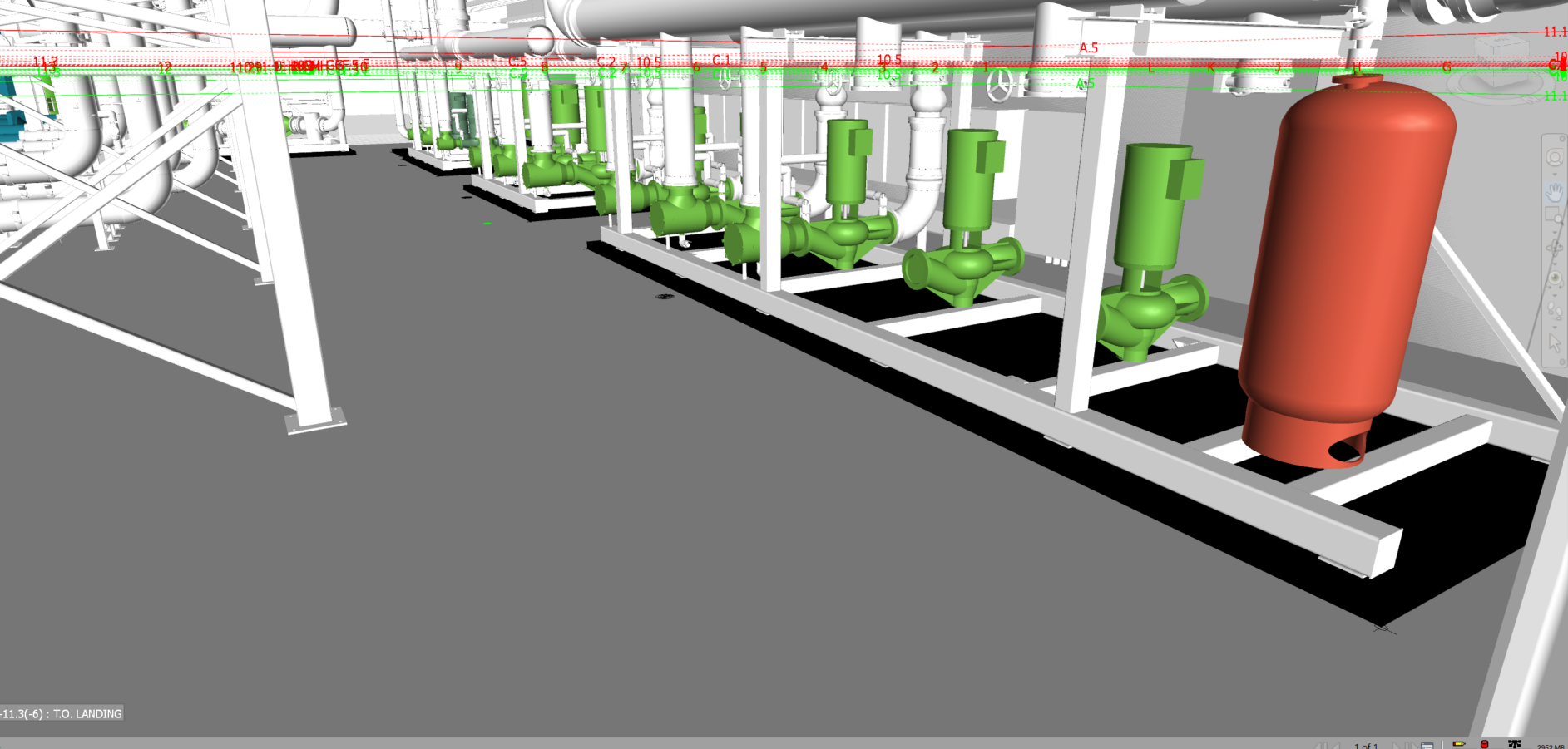

The project required engineering solutions capable of supporting complex manufacturing processes, including underground waste, process chilled water piping, and compressed air systems. As design requirements and equipment selections evolved, iENG’s team adjusted quickly, evaluated changes, coordinated across disciplines, and maintained progress to stay aligned with construction.

To keep delivery on pace, the team collaborated closely with vendors, divided work into manageable phases, and relied on detailed document management across multiple software platforms. Consistent communication and thorough documentation ensured continuity throughout the design and delivery process.

The Fiberon facility highlights iENG’s ability to manage change while maintaining focus on constructability and execution. Through detailed planning, coordination, and adaptability, iENG helped deliver a manufacturing environment built for reliable, long-term performance.

Swift analysis, teamwork and execution bridged the gap between challenges that could stall progress and resilience that moved the project forward. Our team’s designing prowess, tenacity, and steadfast persistence to deliver solutions and value brought to life tangible results that can be seen and experienced!